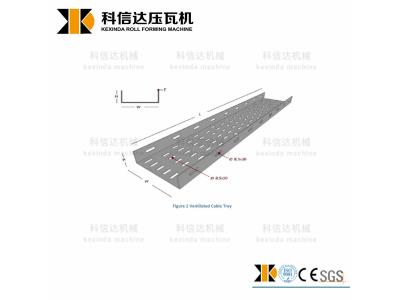

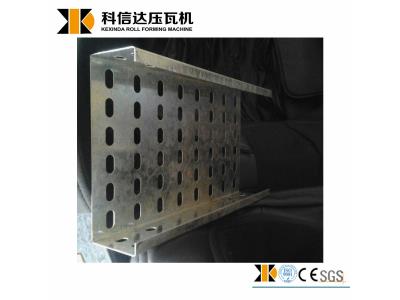

Cable Tray Sheet Roll Forming Machine/ Cable Tray Machine/ Cable Machine Manufacturer

- Product Details

- Company Profile

Cable Tray Sheet Roll Forming Machine/ Cable Tray Machine/ Cable Machine Manufacturer

Cable Tray Sheet Roll Forming Machine/ Cable Tray Machine/ Cable Machine Manufacturer

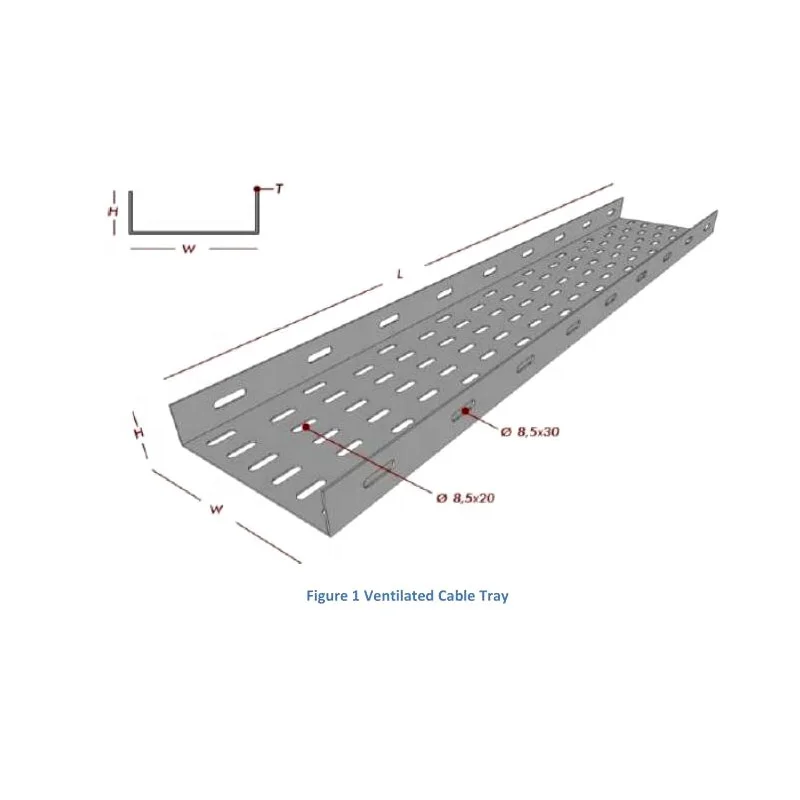

Specification:

Technique parameters of the processing line

(1) Plate Material: Galvanized plate/strip steel

(2) Thickness of the plate : 1.5-2mm(different thickness is ok)

(3) Machine body :350mm H steel

(3) Wall thickness of the main forming machine: 18mm steel plate

(4) Outside debugging to change sizes

(5) Transmission chain : 2’’

(7) Reducer :15kw Xingxing Cycloid which works stably and no noise.

(8) Seam type semi-mat

(9) Roller material: GCr15 with quenched treatment 62-64°C

(10) Rollers14 steps including 9 shafts for leveling.

(11) 4 steps side wheels on the coil-input part for avoiding coil-deviation

(12) Forming part adopts side wheel rotation forming to reduce friction between rollers and coil. Easy and fast debugging

(13) Diameter of active shaft: 80mm, 45# steel

(14) Hydraulic pump power: 7.5KW

(15) PLC control systerm with inverter

(16) Woking Speed: 8-12m/min

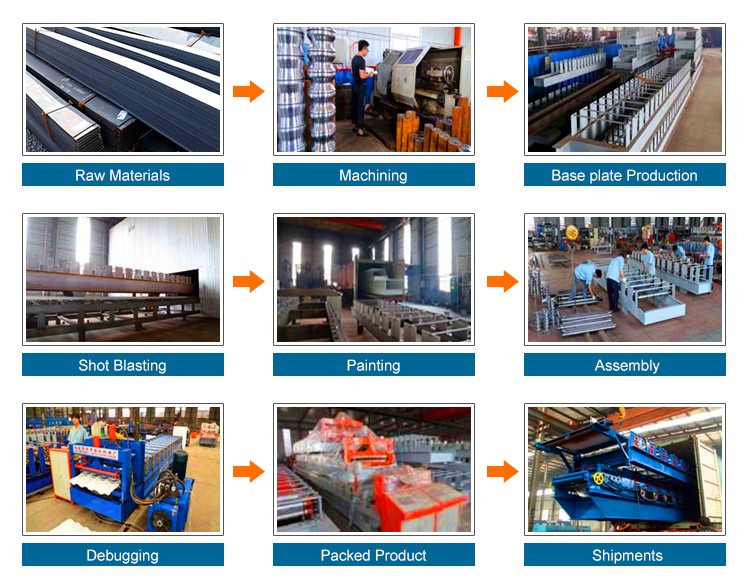

Prodction process

Hot sales

Packaging & Shipping

Our Services

Guarantee:

12 Months guarantee. if some part of the machine is broken. we will supply the best part,but if the damaged parts due to operate error,buyer will pay for the shipping fee.

After-sale service:

We sent technician to your country to fix the machine.the buyer shoule bear all the cost includng:visa,roundtrip ticket and suitable accommodation,also buyer should pay the salary 100USD/DAY.

Company Information

Botou Kexinda Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Free Member

Free Member 0

0 Chinese Supplier

Chinese Supplier