Sandwich Panel Roll Forming Machine

- Product Details

- Company Profile

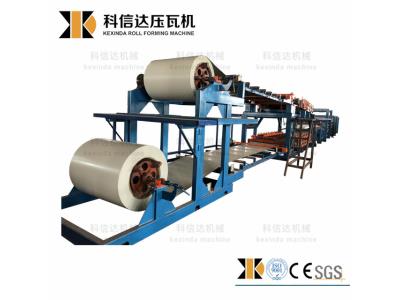

Sandwich panel production line is especially designed for producing insulation composite board. With stepless speed regulation system, it is able to produce corrugated composite panel efficiently at one time. Sandwich panel roll forming machine has been an indispensable device in fabricating roof panels and wall panels in plants and warehouses, among other buildings.

Sandwich panel production line is especially designed for producing insulation composite board. With stepless speed regulation system, it is able to produce corrugated composite panel efficiently at one time. Sandwich panel roll forming machine has been an indispensable device in fabricating roof panels and wall panels in plants and warehouses, among other buildings.

Features

1. The motor power of the sandwich panel roll forming line is 4kw, and the production speed reaches 6m/min. With the stepless speed regulation system, the efficiency of the roll forming line is optional within 0-6m/min.

2. When producing EPS sandwich panel, the speed is generally controlled at 2-6 m/min. It will be slightly lower for making rock wool board (depends on actual needs)

3. The composite panel production line is equipped with K-9 glue metering pump, featuring low rotating speed and high accuracy. The glue is fed at a rate of 0.1-2.0 kg/min. It is controlled by frequency converter.

4. The thickness of the composite panel the roll forming unit can produce is varied from 50mm to 250mm. By adjusting the upper and lower rack, and the distance between the cutter holder and the material feeding rack, we can get sandwich boards with different thickness and specifications.

5. Total installed capacity: 34KW; total weight (including accessories): 17.5t.

6. Dimension of the panel roll forming machine: 12500 (16000 for rock wool boards) X2200X2800; the roll former for 5 type EPS sandwich panel adopts 23 rubber shafts and 160X80 square tubes with thickness of 6mm; the roll former for 7 type composite rock wool panel employs 45 rubber shafts, and upper and lower independent glue supply. It is equipped with 1.7m rock wool panel conveyor belt, with the diameter of the drive shaft to be 50mm; length of the machine frame is up to 9m; the roll former is welded with 180X80 square tubes which thickness is 8mm.

Requirements for Factories:

The factories where our EPS sandwich panel production line are applied can be either flatroof or sloped-roof type. The height of the cornice should be larger than 5m, and the effective width should be at least 45m. The floor of the factory should be flat and concrete. For foundation of the roll forming line, it is required to be to be 380V, and the total installed power is 34kw. It is necessary for the factory to be equipped with 0.4-0.6MPa compressed air supply and illumination devices. The roll forming machine shares the same power supply with the auxiliary devices. The fluctuation of voltage should be no more than 10%, or it may lead to an abnormal running of the system.

The stroke is no less than 29m, the load for a lifting process is larger than 5000kg, and the lifting height is no less than 3.9m. For daily production and maintenance, about 6-10 people are needed, with 3-4 operators for some core processes included.

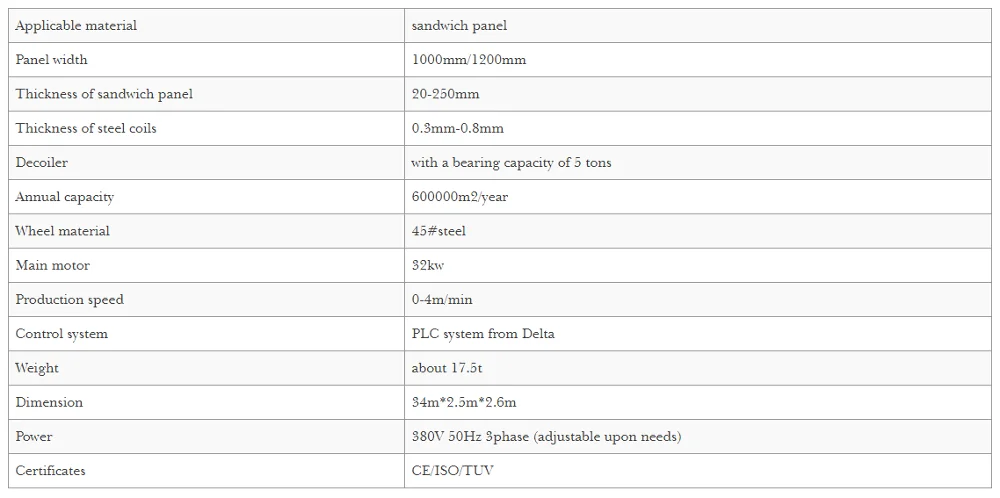

Technical Parameters

contact with Roy Gao to discuss the order,

whatsapp: 0086 178 9761 0680,

0086 159 3271 2693

Sandwich Panel Roll Forming Machine

Sandwich Panel Roll Forming Line

Eps Sandwich Panel Line

Mineral Wool Sandwich Panel Line

Sandwich Panel Roll Former

Composite Panel Roll Forming Line

New Production Line 2018 type

Overseas Engineer Service

Warranty: 2years.

During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged, those new spare

parts will be supplied free by us but the freight charges should be bore equally by both parties.

We will provide the technical support for whole life of the equipment and oversea engineers are available.

Q&A:

1.Why we should purchase machine from you?

We are manufacturer, almost company said they are manufacturer more than 20years in internet, but there is no possible for all

of them.But we are true one the leading manufacturer since 1998, in the beginning we supply for trading company, and since 2008

we start exporting by ourself, we have professsional marketing team and after sales team. you will enjoy the cooperation with us.

2.How about your price and quality?

We always think quality is more important than price, of course as long as your purchase from China, not Germany or Italy, the price

is always good. All of our customers have a consensus that our quality is best in Botou, price is reasonable enough.

3.If any case the machine is something wrong in our site how to do?

We apply engineers oversea service since 2007. If any case we can send our engineers to your site, you should pay USD100 per day for it.

We provide the technical support for the whole life of the equipment and free training.

4.Where is the nearest airport and seaport?

We always welcome you visit our factory, you can by air to Beijing or Tianjin airport and then to Cangzhou west railway station by railway,

I will be there to pick up you, and then you don't worry about anything.

Free Member

Free Member 0

0 Chinese Supplier

Chinese Supplier