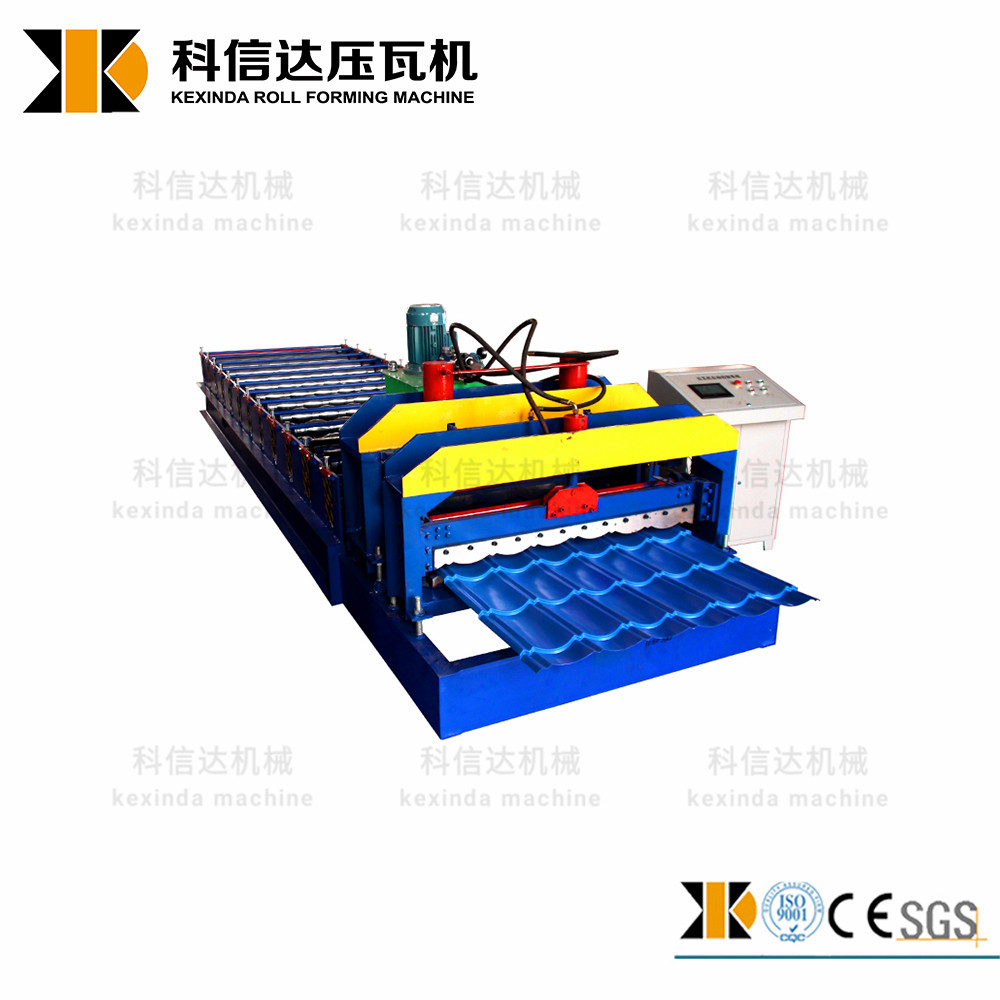

KEXINDA CHINA Colorful Zinc Sheet 828 Glazed Tile Roofing Panel Roll Forming Machine

- Product Details

- Company Profile

KEXINDA CHINA Colorful Zinc Sheet 828 Glazed Tile Roofing Panel Roll Forming Machine

Product Description

Product Description

Botou colorful zinc sheet 828 glazed tile roofing panel roll forming machine

Main parameters

1.Echnical parameters

Name | Botou colorful zinc sheet 828 glazed tile roofing panel roll forming machine |

Suitable to process | Color steel plate, galvanized sheet, aluminum coils and etc. |

Width of the feeding material | 1000mm |

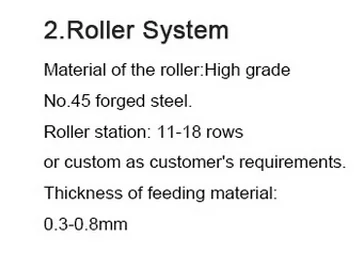

Roller station | 11 rows |

Thickness of feeding material | 0.3-0.8mm |

Power Supply | 380V, 3-Phase,50Hz |

Productivity | 8-12m/min |

Rollers' material | 45# steel |

Diameter of shaft | 75mm |

Roller Diameter | 80mm |

Wall thickness of main forming machine | 14mm steel plate |

Main forming machine body | 300 mm H steel |

Motor power | 4+3kw |

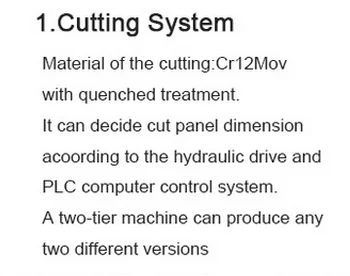

Cutter Standard | GCr12 |

Size | 7500*1500*1600mm |

Weight | About 3.5T |

Custom | According to customer's requirements |

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

Detailed Image

Detailed Image

Packing & Delivery

Packing & Delivery

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Certifications

Certifications

Our Company

Our Company

Established in 1998. Kexinda has accumulated rich experience in producting tile roll forming machine. Near 20 years' development has made Kexinda the most powerful roll forming equipment supplier in Northern China. We are now staffed by over 200 people.The two production regions in Kexinda span an area of 50 thousand m2. We have established 5 large workshops, including plants for spare parts machining, machine welding, assembly, andsurface treatment.

Free Member

Free Member 0

0 Chinese Supplier

Chinese Supplier