shutter door machine

- Product Details

- Company Profile

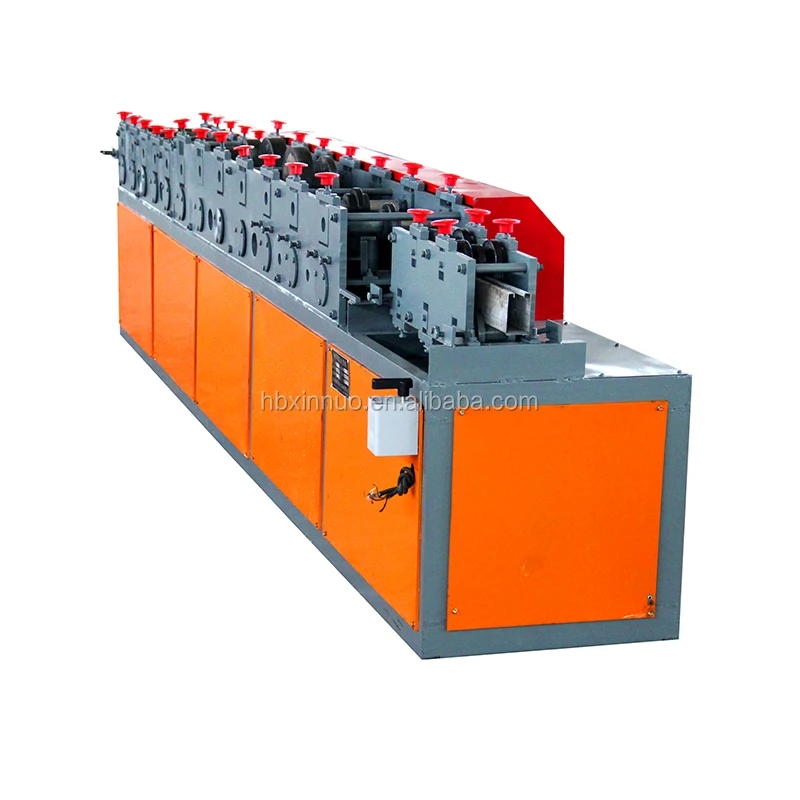

xinnuo shutter door machine iron sheet rolling machine rolling shutter machine price

xinnuo shutter door machine iron sheet rolling machine rolling shutter machine price

Product Description

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

Main parameters

1.Echnical parameters

Name | fully automatic rate galvanized slat sliding door guide rail steel roll forming machine |

Suitable to process | Color steel plate, galvanized sheet, aluminum coils and etc. |

Width of the feeding material | 100-160mm |

Roller station | 10-15 rows |

Thickness of feeding material | 0.3-0.8mm |

Power Supply | 380V, 3-Phase,50Hz |

Productivity | 10-20m/min |

Rollers' material | 45# steel |

Diameter of shaft | 75mm |

Roller Diameter | 50mm |

Wall thickness of main forming machine | 14mm steel plate |

Main forming machine body | 300 mm H steel |

Motor power | 4+3kw |

Cutter Standard | GCr12 |

Size | 7500*1500*1600mm |

Weight | About 2.5T |

Custom | According to customer's requirements |

Product Pictures

Detailed Images

Our Services

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller’s factory while before delivery.

Delivery: 30 days after receipt of advance payment

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa, Round trip tickets and suitable accommodation, also buyer should pay salary 80USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee.

Company Information

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Strong technical resources are the most stable guarantee for our products' quality. We adopt computer software for design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day by day!

Our company has matured after-sale service network, we could provide efficient and satisfactory service for you throughout the period of our cooperation.If necessary, we can supply you with local technical support and send technicians to for installation and operation training.

FAQ

Free Member

Free Member 0

0 Chinese Supplier

Chinese Supplier