cable tray making machine drywall manufacturing machine roofing sheet making machine

- Product Details

- Company Profile

cable tray making machine drywall manufacturing machine roofing sheet making machine

cable tray making machine drywall manufacturing machine roofing sheet making machine

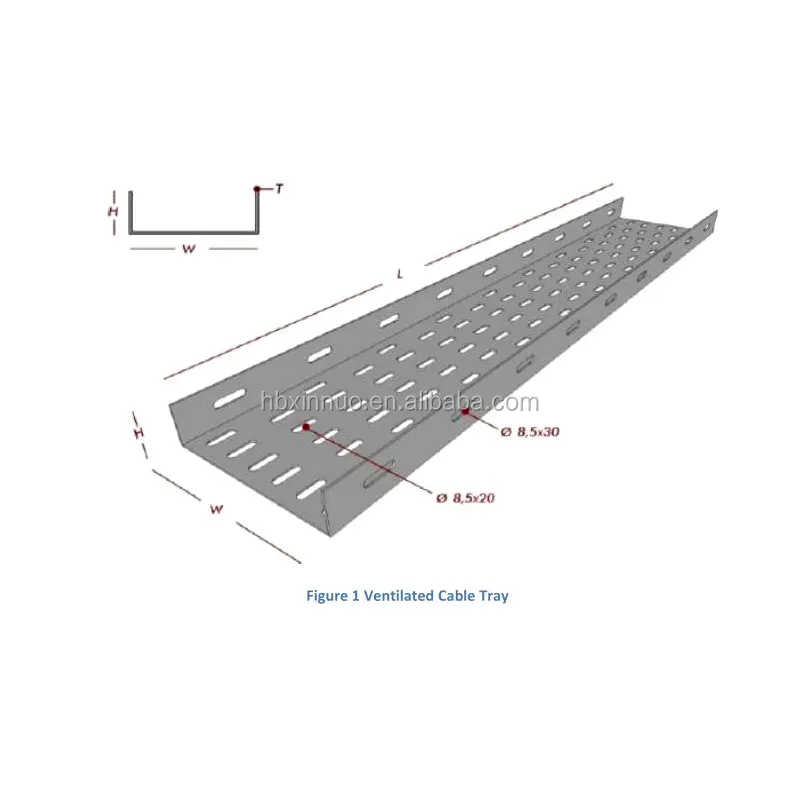

Product Description

Cable ladder tray making machine economical Price

Equipment components: Manual uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting, run out table

Main parameter Cable ladder tray making machine economical Price

No. | Cable ladder tray making machine economical Price | ||

1 | Suitable to process | Color steel plate | |

2 | Width of the plate | 300-900mm | |

3 | Rollers | 18-22rows | |

4 | Dimensions | 10.5*1.6*1.5m | |

5 | Power | 11+4kw | |

6 | Thickness of the plate | 0.5-1.2mm | |

7 | Productivity | 4-6m/min | |

8 | Diameter of the roller | 90mm | |

9 | Weight | About 8.0 T | |

10 | Voltage | 380V 50Hz 3phases | |

11 | Rolling material | Carbon Steel 45# | |

12 | Material of the cutting plate | Cr12 | |

13 | Processing precision | Within 1.00mm | |

14 | Control system | PLC control | |

Product Pictures

Cable ladder tray making machine economical Price

1)Decoiler

Decoiler Type : manual decoiler

weight capacity of decoiler : 5.0T

2)Feeding and Leveling Device

It used for making the material flat before feeding into the roll forming machine

Our Advantage

Our machine | Influence of the machine | |

Main forming machine body | High strength H300 or H350 steel. machine through milling machine after welding | Sturdy and durable, ensure the plate standard |

Material of the roller | GCr15 | Ensure the forming effect of the panel and the use age will be longer,the surface of the panel |

Material of the cutting | Cr12 steel with quenched treatment | Cutting is out of shape not easily and use age will be longer,the panel size precision |

Material of the active shaft | High grade No.45 forged steel, Shaft diameter is 80 or 75mm. | Improve the integrated mechanic feature of the shaft and keep product standard |

Control system | PLC control system,some elements are imported from Japan and Germany | Machine become more accurate and more stable |

Free Member

Free Member 0

0 Chinese Supplier

Chinese Supplier