rain gutter making machine automatic round steel gutter downpipe machine

- Product Details

- Company Profile

rain gutter making machine automatic round steel gutter downpipe machine

rain gutter making machine automatic round steel gutter downpipe machine

Hot Sales

Product Description

1. The advantage of water gutter cold roll forming machine

gutter cold roll forming machine can bend the roll formed pipe, and let the drainpipe and the bending connect to be the whole.The product after roll forming has long working time than the tranditional ppc pipe, and not aging. It can make the project more integrate, and help to enhance the image of the all project.

gutter cold roll forming machine is composed of uncoiler, the feed leading table, the main machine, the formation cutting device, hydraulic system, control system and the product bracket.

2.Main parameter of water gutter cold roll forming equipment

No. | main parameter of gutter roll forming machine | ||

1 | Suitable to process | Color steel plate | |

2 | Width of the plate | 200-600mm | |

3 | Rollers | 14-16rows | |

4 | Dimensions | 8.6*0.8*1.2m | |

5 | Power | 4+3kw | |

6 | Thickness of the plate | 0.3-0.8mm | |

7 | Productivity | 8-12m/min | |

8 | Diameter of the roller | 52mm | |

9 | Weight | About 4.5 T | |

10 | Voltage | 380V 50Hz 3phases | |

11 | Rolling material | Carbon Steel 45# | |

12 | Material of the cutting plate | Cr12 | |

13 | Processing precision | Within 1.00mm | |

14 | Control system | PLC control | |

15 | Side panel of machine | 14mm | |

16 | Main structure of the machine | 300 H steel | |

17 | Weight | About 4.5 T | |

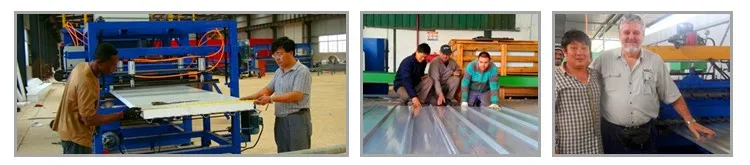

3. some pictures of water gutter cold metal sheet roll forming machine

5.Packaging & Shipping

Packaging Details: | Main machine is nude, the computer control box is packed with wooden frame. |

Main machine is nude in the container, the computer control box is packed with wooden packaging. | |

Delivery Detail: | 20 days |

Our Company

6.Our Services

Our Services

Guarantee:

12 Months guarantee. if some part of the machine is broken. we will supply the best part,but if the damaged parts due to operate error,buyer will pay for the shipping fee.

After-sale service:

We sent technician to your country to fix the machine.the buyer shoule bear all the cost includng:visa,roundtrip ticket and suitable accommodation,also buyer should pay the salary 100USD/DAY

7.Company Information

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional

roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z

shape purline machines, highway guardrail roll forming machine lines, sandwich panel production

lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe

machines, gutter machines, etc.

Strong technical resources are the most stable guarantee for our products' quality. We adopt computer software for design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day by day!

Our excellent and professional after-sales team will supply perfect services. We have a detailed manual book and can supply you with technical support via phone and network. If necessary, we can supply you with local technical support and send technicians to for installation and operation training.

FAQ

Free Member

Free Member 0

0 Chinese Supplier

Chinese Supplier