seam lock roll forming machine

- Product Details

- Company Profile

seam lock roll forming machine

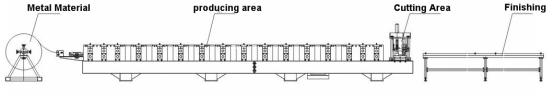

Machine including:

3 ton manual de-coiler x1 set

Main roll forming machine x1 set

Seam lock machine x2 set

Hydraulic cutting system x1 set

Hydraulic station x1 set

PLC Control system x1 set

Collection table x1 set

Machine process:

Parameters:

Manual Decoiler | 1: Max width of raw material :700mm 2: Capacity:3000kgs 3: Inner diameter of coil: 508±30mm |

roll forming machine |

4. Two Main motor power station: 7.5kw Frequency speed control 3. Forming speed about:16 m/min 4. Quantity of rollers: 16 rollers 6. Shaft Material and diameter: 45# forge steel Φ75mm. 7.Material Of The Stations: 18mm A3 steel 8.Tolerance: 10m+-1.5mm 9.Way Of Drive: Chain 10.Material of forming rollers: Gcr15, hard chrome coated 11.Material of cutter blade: Cr 12 mould steel with quenched treatment 58-62℃ 12: Voltage: 380V/ 3phase/ 50 Hz(according to customer choice) 13.Machine weight :Around 9 tons |

Cutting (hydraulic guide) | 1.Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. 2.Material of blade: GCR12with heat treatment 3.Length measuring: Automatic length measuring 4.Tolerance of length: 10+/- 1.5mm 5.the cutting part include three part blade. 6.hydraulic power:4kw. Max 10Mpa. |

PLC control system

| 1.Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (or customized ) 2.Automatic length measurement: 3.Automatic quantity measurement 4.Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved 5.Length inaccuracy can be amended easily 6.Control panel: Button-type switch and touch screen 7.PLC is Delta, the touch screen is Winview, the inverter is Schneider, the encoder is Omron |

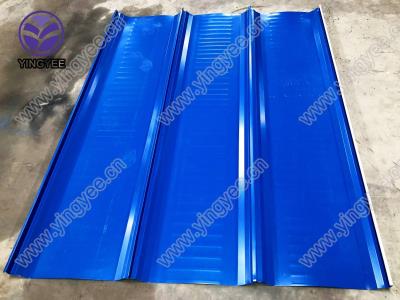

Color | Dark Blue(or any customized color before purchase ) |

Electronic seam lock machine | Include seam lock machine with good quality 2 set. |

Manual seamer | 2 sets |

More machine photos:

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier